Dye Sensitized Solar Cells (DSSC) are widely regarded as the most promising third generation photovoltaic (solar) technology. These cells are the closest mankind has come to replicating nature’s photosynthesis. Paying homage to its inventor Professor Michael Gräetzel we call it GCell.

Advantages of GCell – the smart choice

GCell Dye Sensitized Solar Cells (DSSC) are a smart choice for energy harvesting when integrating a solar module into an electrical device using a rechargeable battery or super capacitor.

Superior low light performance

Suitable for shaded and diffuse light locations

Works in a wide range of lighting conditions

Manufactured in the UK

Uses low-energy consumption, high-efficiency, roll-to-roll techniques

Attuned to indoor use

Designed specifically for indoor energy harvesting product applications

Robust and lightweight

Suitable for everyday usage without fear of breakages

Lightweight for use in portable applications and cheaper to transport

Thin and flexible

Adds minimal amount of thickness for versatile integration

Withstands flexing over 10,000 times

When to use GCell – comparison of technologies

GCell Dye Sensitized Solar Cells (DSSC) are suitable for a broad range of electronic application and offers many benefits over other solar technologies.

| Technology comparisons | GCell | a-Si | c-Si | OPV | CdTe |

|---|---|---|---|---|---|

| Low-light or diffused light locations |  |  | |||

| Ecologically friendly solar |  |  | |||

| Indoor applications |  |  | |||

| Portable wireless applications |  |  | |||

| Flexible |  | ||||

| Thin |  |  | |||

| Ease of integration |  | ||||

| Lightweight |  |  |

GCell material characteristics – precision engineered nanomaterials

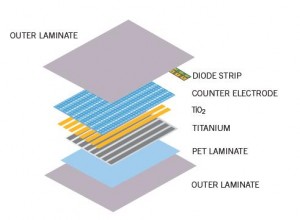

GCell Dye Sensitized Solar Cells (DSSC) are designed using the most advanced photo-reactive nano-engineered materials using an inexpensive, energy-efficient manufacturing process.

Flexible – Tested to withstand flexing over 10,000 times around a 25mm radius with no measurable drop in performance.

Robust – Tough enough to withstand impact, drop tests and compression making it suitable for everyday usage without fear of breakages.

Thin – Adds minimal thickness to any product application; approximately the thickness of a credit card.

Lightweight – Easier to transport, lower logistical costs and adds minimal weight to any product application.

Versatile – Easily integrated into a wide variety of product applications.

Durable – Excellent vapour barrier properties using high-performance polymer front sheet barrier film with high light transmission coupled with a base aluminium PET foil.